Product categories

CONTACT US

- ADD:Hongzhuang Road, East Town Industry Area, Yaoguan Town, Wujin District, Changzhou City, Jiangsu Province, PR. China

- Mobile Phone:+86-15961181358

- Fax:+86-519-88700526

- E-mail:wk1358@dongchuan.cn

Home >Products >Engineering Chain & Conveyor Chain >Scraper Chain for Grain Machines (Welded Steel Chain)

Scraper Chain for Grain Machines (Welded Steel Chain)

Scraper Chain for Grain Machines (Welded Steel Chain)

- Model: Scraper Chain for Grain Machines

wk1358@dongchuan.cn

wk1358@dongchuan.cn

Introduction

Scraper Chain for Grain Machines

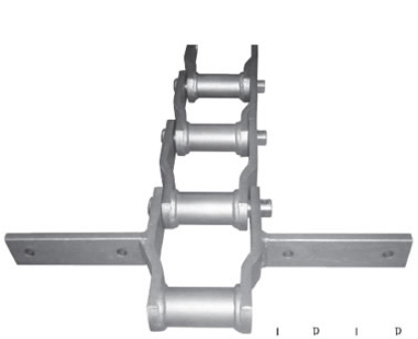

The welded steel chain is also called scraper chain, and is widely used throughout the grain processing industry. It is compatible with abrasive materials, and mainly supports low speed load carrying. Additionally, it is able to work in severe environments with heavy dust and strong impacts.

This type of conveyor chain is composed of bended sidebars which are exactly the same. The sidebars are connected with each other directly without other types of link plates. The chain link can be either odd or even number. The sleeve and sidebars are welded together, which ensures simple but durable structure.

In order to make scraper chains with improved quality and extended service life, we adopt automatic welding robots to weld the bushing and sidebar together. The precision equipment guarantees uniform and stable welding quality. Meanwhile, we conduct inspections according to the Quality Control Standard of international leading roller chain manufacturers. Additionally, according to the proportion of 5%, our welded steel chain products undergo conduct destructive tests to ensure approved welding quality. Our patented high frequency induction heating treatment for the pins offers higher strength while improving the wearing resistance.

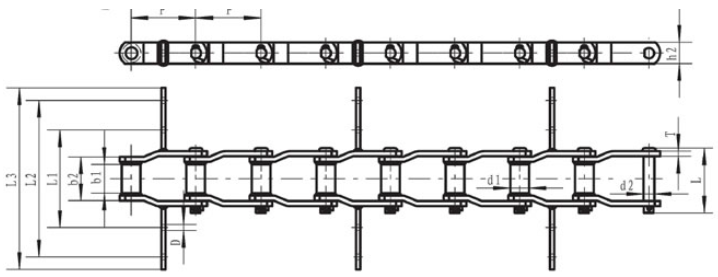

Technical Specifications

| Chain No. | Pitch P (mm) | Outer diameter of bushing d1 (mm) | Diameter of pin d2 (max) (mm) | Height of sidebar h2 (max) (mm) | Inner width between small ends b1 (mm) | Outer width between small ends b2 (mm) | Thickness of sidebar T (mm) | Dimension of scraper | Tensile strength Q (min) (KN) | |||

| L1 (mm) | L2 (mm) | L3 (mm) | D (mm) | |||||||||

| 78.1 | 26.97 | 14.35 | 31.8 | 38.1 | 57.4 | 6 | 110 | 150 | 170 | 10 | 132 | |

| 78.1 | 26.97 | 14.35 | 31.8 | 38.1 | 57.4 | 6 | 130 | 180 | 220 | 10 | 132 | |

| 78.1 | 25.4 | 14.29 | 32 | 31.8 | 57 | 6.4 | 155 | 235 | 265 | 14 | 100.1 | |

| 78.1 | 25.4 | 14.29 | 32 | 31.8 | 57 | 6.4 | 160 | 320 | 350 | 14 | 100.1 | |

| 101.6 | 36.5 | 19.05 | 38.1 | 41.28 | 69.9 | 9.5 | 165 | 235 | 265 | 14 | 300 | |

| 101.6 | 31.75 | 19.05 | 38.1 | 41.28 | 66.9 | 8 | 150 | 190 | 270 | 12 | 300 | |

| 101.6 | 36.5 | 19.05 | 38.1 | 41.28 | 69.9 | 9.5 | 170 | 280 | 310 | 14 | 300 | |

| 101.6 | 31.75 | 19.05 | 38.1 | 41.28 | 69.9 | 9.5 | 170 | 290 | 330 | 12 | 300 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 59 | 91.2 | 10 | 230 | 370 | 430 | 14 | 356 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 66 | 98 | 10 | 230 | 370 | 430 | 14 | 356 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 59 | 91.2 | 10 | 224 | 374 | 434 | 14 | 356 | |

| 153.67 | 44.45 | 25.05 | 50.8 | 76.2 | 111.8 | 12.7 | 201.4 | 441.4 | 498 | 13 | 378.1 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 66 | 98 | 10 | 230 | 500 | 560 | 14 | 356 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 66 | 102 | 12 | 224 | 534 | 594 | 14 | 511 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 66 | 102 | 12 | 224 | 504 | 564 | 14 | 511 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 68 | 104 | 12 | 230 | 450/670 | 730 | 14 | 511 | |

| 153.67 | 44.45 | 28.75 | 60 | 73 | 109 | 12 | 226 | 450/674 | 734 | 14 | 543 | |

| 153.67 | 44.45 | 28.75 | 60 | 73 | 109 | 12 | 230 | 560/890 | 950 | 14 | 543 | |

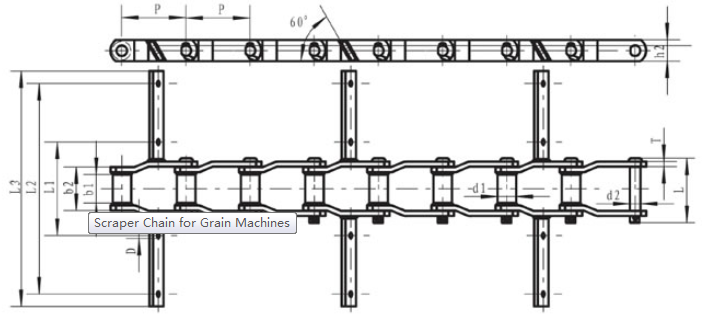

| Chain No. | Pitch P (mm) | Outer diameter of bushing d1 (mm) | Diameter of pin d2 (max) (mm) | Height of sidebar h2 (max) (mm) | Inner width between small ends b1 (mm) | Outer width between small ends b2 (mm) | Thickness of sidebar T (mm) | Dimension of scraper | Tensile strength Q (min) (KN) | |||

| L1 (mm) | L2 (mm) | L3 (mm) | D (mm) | |||||||||

| 101.6 | 31.75 | 19.05 | 38.1 | 41.28 | 69.9 | 9.5 | 154 | 294 | 334 | 12 | 300 | |

| 153.67 | 44.45 | 25.2 | 50.8 | 76.2 | 111.8 | 12.7 | 230 | 350 | 400 | 14 | 378.1 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 59 | 91.2 | 10 | 224 | 374 | 434 | 14 | 356 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 66 | 102 | 12 | 224 | 504 | 564 | 14 | 511 | |

| 153.67 | 44.45 | 25.4 | 50.8 | 66 | 102 | 12 | 224 | 534 | 594 | 13 | 511 | |

| 153.67 | 44.45 | 28.75 | 50.8 | 73 | 109 | 12 | 226 | 636 | 696 | 14 | 543 | |

| 153.67 | 44.45 | 28.75 | 60 | 73 | 109 | 12 | 226 | 450/674 | 734 | 14 | 543 | |

| 153.67 | 44.45 | 28.75 | 60 | 73 | 109 | 12 | 230 | 560/890 | 950 | 14 | 543 | |

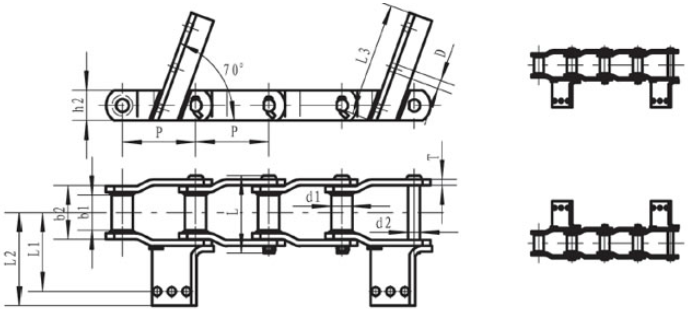

| Chain No. | Pitch P (mm) | Outer diameter of bushing d1 (mm) | Diameter of pin d2 (max) (mm) | Height of sidebar h2 (max) (mm) | Inner width between small ends b1 (mm) | Outer width between small ends b2 (mm) | Thickness of sidebar T (mm) | Dimension of scraper | Tensile strength Q (min) (KN) | |||

| L1 (mm) | L2 (mm) | L3 (mm) | D (mm) | |||||||||

| 153.67 | 44.45 | 28.57 | 63.5 | 73 | 111.76 | 12.7 | 163.4 | 193.4 | 240 | 18 | 542 | |

Related Names

Drag Conveyor Chain | Mild Steel Chain | Grain Handling Machine Chain

Immediately Consult

OTHER PRODUCTS

NEW PRODUCTS

Meet the application requirements under severe environments, it is especially crafted to support high load carrying under high temperature conditions. For instance, our alloy steel chains for heavy duty uses adopt special bearings as the rotational part, so as to ensure increased load carrying capacity and reduced operational risks.

The sugar machine chain, with its high-strength materials,precise design, modular structure,and self-lubricating system,demonstrates advantages such as high efficiency,durability,low maintenance costs,and high adaptability in the sugar industry.Its high load capacity,low failure rate,smooth operation, and long lifespan make it an indispensable key equipment in sugar production lines. Our chains meet international leading standards and have been validated for quality reliability through rigorous destructive testing.The chain is suitable for various processing scenarios and can provide customized solutions based on needs,ensuring optimal performance and long-lasting durability.

We can offer a wide range of sugar industry use chain attachments. These chain attachments are specially processed to offer higher strength and corrosion resistance, so as to accommodate the operating environment of the sugar making industry use transmission chains.