- ADD:Hongzhuang Road, East Town Industry Area, Yaoguan Town, Wujin District, Changzhou City, Jiangsu Province, PR. China

- Mobile Phone:+86-15961181358

- Fax:+86-519-88700526

- E-mail:wk1358@dongchuan.cn

What is a cast chain?

Have already visited 8305/22/2025In industrial equipment and mechanical transmission systems, cast chains play an indispensable role. However, many users still have questions about their specific definitions, manufacturing processes, and applicable scenarios. This article will provide a comprehensive analysis of "What is a cast chain?" in a simple and understandable way, helping you quickly grasp their core value and application logic.

Definition and Basic Structure of Cast Chains

1.1 What is a Cast Chain?

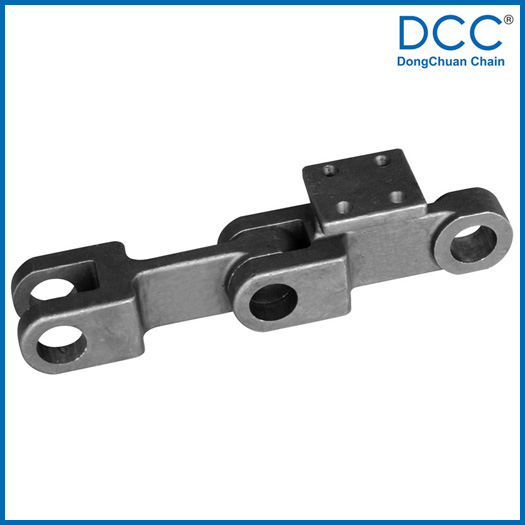

A cast chain is a metal chain formed through a casting process, with its links and connecting components integrally molded using die-casting technology. Compared with traditional welded or assembled chains, it has a tighter structure and higher durability, making it suitable for high-load and high-wear industrial scenarios.

1.2 Typical Structure of Cast Chains

Cast Links: Formed by filling molds with molten metal to ensure shape consistency.

Pins: Core components connecting the links, requiring high hardness and fatigue resistance.

Attachments: Customized as needed, such as adding scraper plates or fixing devices.

Analysis of Cast Chain Manufacturing Processes

2.1 Precision Mold Design

Cast chain production begins with high-precision mold development. Molds must meet link dimensional tolerances (±0.1mm) and reserve shrinkage allowances to address metal deformation during cooling.

2.2 Material Selection and Smelting

Common materials include high-carbon steel or special alloys. The smelting temperature must be strictly controlled between 1500°C and 1600°C to ensure metal fluidity and final strength.

2.3 Casting and Post-Processing

Casting Molding: Molten metal is poured into molds and demolded after cooling.

Heat Treatment: Hardness and toughness are improved through quenching and tempering.

Surface Treatment: Processes like galvanizing or spraying enhance corrosion resistance.

Core Application Fields of Cast Chains

3.1 Industrial Mechanical Transmission Systems

Cast chains are widely used in equipment such as conveyors and hoists, and their high load-bearing capacity supports continuous operation.

3.2 Agriculture and Heavy Equipment

In harvesters and tractors, cast chains can withstand harsh environments such as sand and moisture, reducing maintenance frequency.

3.3 Logistics and Transportation Industries

Sorting equipment in automated warehousing systems relies on cast chains for precise transmission, ensuring efficient logistics operations.

3.4 Energy and Mining Sectors

In mining machinery and power generation equipment, the impact resistance of cast chains can handle extreme working conditions and reduce failure risks.

Three Core Advantages of Cast Chains

4.1 Excellent Durability

The casting process eliminates weld weaknesses in the links, increasing the overall service life by over 30% compared to traditional chains.

4.2 Higher Cost-Effectiveness

Although initial costs are slightly higher, cast chains have lower long-term maintenance costs, making them suitable for enterprises requiring low downtime rates.

4.3 High Adaptability

Supports customized designs, such as special link shapes or additional functional modules, to meet diverse scenario requirements.

How to Choose the Right Cast Chain?

5.1 Clarify Load and Working Conditions

Is it a static load or dynamic load?

Will it be exposed to corrosive substances or high-temperature environments?

5.2 Focus on Materials and Certifications

Prioritize products certified to international standards such as ISO 9001 to ensure material composition and process compliance.

5.3 Testing and Verification

Request fatigue test reports from suppliers to validate actual performance parameters.

Conclusion: Choose Professional Brands for Quality Assurance

The performance of cast chains directly affects equipment efficiency and safety. As a core component in industrial transmission, their design, materials, and processes are all critical. With 20 years of focus on cast chain R&D, DCC provides cost-effective and long-lasting cast chain solutions for customers through advanced automated production lines and strict quality inspection systems.

If you are seeking reliable and durable transmission components, welcome to contact DCC for customized suggestions—let our professional expertise help your equipment operate efficiently!

View More(Total0)Comment Lists